echo edge block

Traditional wood blocking system blows off in a high wind event and takes the roof with it.

The edge blocking is the anchor in high winds because the most extreme pressures from a wind event are at the edge.

ECHO EDGE BLOCKING is tested at hurricane standards to resist the uplift forces at the edge of the building.

Pressure Treated Lumber:

In today’s dollars this 3.8 billion board feet represents $4.7 billion dollars for North America alone!

Expensive, chemically treated, it burns, bugs still like it, eventually rots and requires hundreds of millions of trees every year.

Echo Edge and Echo Coping blocks replace the need for wood blocking in roofing entirely!

It’s faster, therefore cheaper and recycles hundreds of millions of tires as our raw material.

See our easy to use calculator in this section, type in the quantity and watch how many trees you will save and tires you will recycle on just one project…

5 to 7 times faster install

2” to 10” high in 1/2” increments

4 standard sizes (2”, 2.5”, 3”, 3.5”)

No fasteners required. Wood, steel or concrete substrates.

Dade NOA rated at -300 psf at 10” high

ES-1 Certified as well

See calculate button to enter l/f and height needed to see just how many trees you will save and tires that will be recycled on this one project!

Cheaper, stronger, faster, will never rot, moisture and bug proof.

UL Class “A” rated at unlimited slope.

Corner pressure is higher than the edge so if your typical wood nailer is installed without enhanced fastening at the corners, your building is at risk.

Echo Blocks are rated for hurricane force winds “off the shelf” so no enhancements are needed.

Echo Edge Block accommodates the many thickness combinations of insulation boards by providing 1/2” increments!

Simply use a combination of our 4 sizes (2”, 2.5”, 3” and 3.5”) to achieve your desired thickness.

Product arrives in a 4’x4’ pallet with reusable cover. Outside storage the pallets of four standard sizes and know your crews can simply lift the cover and load up whatever thickness needed for the day.

The best part is that once installed, there is no need to protect it. 5,000 hour accelerated aging testing proved it became 30% stronger in all physical property testing post aging.

No more trips to the lumber store picking through stacks of warped lumber that only provide 1-1/2” increments!

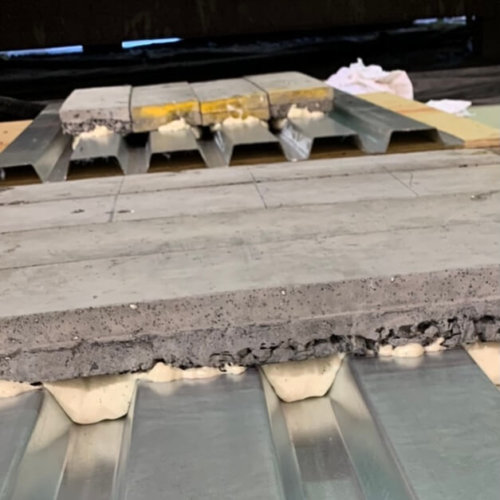

This photo represents an actual uplift test for a Box Gutter that was attached to our 10” high Echo Edge Block.

It is one of the very few tests ever done for a box gutter that resulted in a -300 psf NOA!

It actually did not fail, we simply chose to stop the test once we attained our desired pressure.

Echo Edge Cleats are installed with the Edge Blocks, thereby, saving time and the cost of fasteners.

Safer to install as men are no longer are hanging over the edge to drill and screw the cleat.

This photo was taken on an active school. With no required drilling, the Echo Edge was installed during school hours without disturbing the classroom.

Echo Edge Block, tested at PRI Test labs (-300 psf) NOA, with a 5-1/2”, face drip edge.

Trouble with chemicals:

Pressure treated lumber arrives wet. Wet from chemical treatment, not moisture.

A typical installation showing the chemicals staining the precast wall panels over the course a several weeks.

Contractor was required to rent a man-lift and pressure clean all four walls on this project at a cost of many thousands of dollars.

If it stains concrete, how good can it be for your skin? How about your lungs when it’s cut with a circular saw?

When attaching Echo Block or Echo Edge Block to a steel deck with the AH-160 Tile Foam adhesive, know it has been tested as a bead on top of the flute as well as across the flutes.

Both directions exceeded the Miami Dade test chamber capabilities.

The benefit of attaching with foam is how the foam seals the deck from freely emitting conditioned air out of the edge of the building.

A regulation that is here and soon to be more strictly enforced.

With Echo Edge Blocking and Echo Terrace, this energy saving regulation is already in compliance.

No exposed fasteners with Echo Edge.

In fact there are no fasteners whatsoever as the entire assembly adhered with AH-160 tile foam adhesive.

Clean look, no drilling or expensive fasteners.

Healthier as well as breathing the dust from silica, (concrete dust in photo) is a significant health hazard.

Echo Block has been tested and approved as a Class A, fire rated product at unlimited slope.

In the UL report it also states that any roofing material that is already tested as Class A over concrete, is also approved on Echo Block without additional testing.

Echo Edge Blocks are always numbered by thickness.